The specific process of three-electric system die casting parts

Raw material testing Check documents: each batch of incoming materials must be checked against the delivery note, product name, specification and logo; Appearance: The surface should be clean, free of oil stains, corrosion spots, slag and non-metallic inclusions; the structure of the segment mouth should be dense, without serious segregation, shrinkage cavities, slag and non-metallic inclusions; steel stamps should be applied to each alloy ingot Mark the supplier code; the alloy ingot should be packed according to the furnace number Specifications: The weight difference of each alloy ingot should be within 10%; Chemical composition: check according to the chemical report provided by the raw material supplier; HSF: Check the validity period of the SGS report (1 year); Packaging: The product packaging method needs to be unified and the packaging is intact; the quantity and weight meet the requirements of the delivery note.

Aluminum ingot melting slag exhaust Aluminum water slag remover and refining degasser are special and necessary purification equipment for non-ferrous metal casting industry. The degassing and slag removal machine uses a rotor that rotates at high speed and injects inert gas and granular flux to break up large bubbles of inert gas into very fine small bubbles and disperse them evenly in the molten metal. By reducing the diameter of the bubbles, the total surface area of these bubbles increases dramatically, which allows more inert bubble surfaces to come into contact with hydrogen and impurities in the molten metal and bring these harmful substances to the liquid surface.

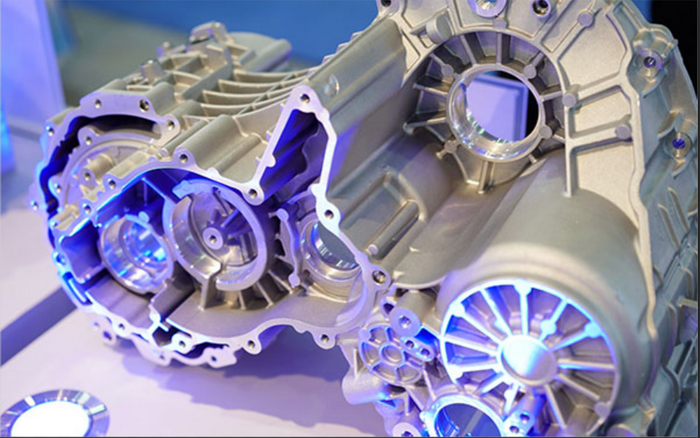

Die casting There are 18 sets of 400-2000 tons of Hong Kong LK die-casting machines in the die-casting trial workshop, which can meet the requirements of different sizes of test castings. The 1000kg centralized melting furnace and 5 dumping furnaces can produce more than 5 grades at a time to meet the needs of different grades of aluminum alloys. Require.

Die casting mass production There are 8 sets of Hong Kong Lijin die-casting machines with a capacity of 400-2000 tons in the die-casting mold trial workshop, which are equipped with automatic feeding manipulators around the die-casting machine, robot spraying system, robot pick-up and mosaic system, die-casting gate cutting device, die-casting coding machine, fast A variety of automation equipment such as mold changing system, product conveying device, intelligent CNC post-processing, etc., can meet the requirements of mass production of castings.

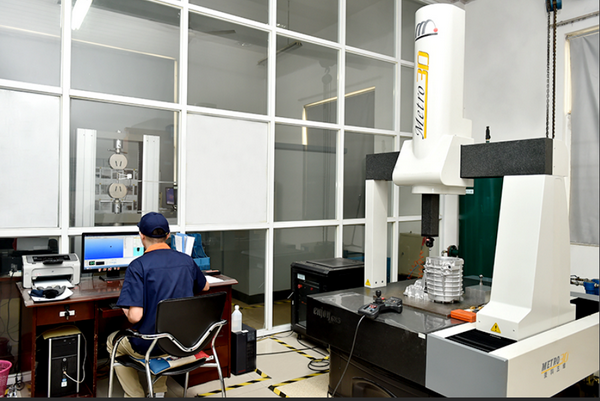

Hair embryo detection The Boway measurement room built according to laboratory standards is equipped with three coordinates, X-ray flaw detectors, spectrometers, profilers, cleanliness meters, metallographic microscopes, salt spray testing machines and other castings on the basis of ensuring constant temperature and humidity. Testing Equipment.

Casting X-ray inspection In casting, castings often have trachoma, which has always been a problem. The trachoma on the surface of the casting can be seen or identified directly with the naked eye, but the internal trachoma cannot be seen with the naked eye. This requires a "special" "Equipment for inspection, which is what we usually call X-ray non-destructive testing equipment. It can clearly detect the internal structure of the casting through the principle of X-ray transmission, and easily display the defects such as sand holes, cracks, shrinkage porosity, and shrinkage cavity inside the casting on the computer screen, and effectively find abnormalities in the casting production process. situation and provide effective guidance for timely improvement of deficient processes.