Mold Making Process

Ⅰ. Acceptance of assignment

The task book for molded plastic parts is usually proposed by the part designer, and its content is as follows:

- The approved drawings of the formal parts, and indicate the grade and transparency of the plastic.

- Instructions or technical requirements for plastic parts.

- Production output.

- Samples of plastic parts.

Usually the mold design task book is proposed by the plastic part craftsman according to the task book of the molded plastic part, and the mold designer designs the mold based on the task book of the molded plastic part and the mold design task book.

Ⅱ. Collect, analyze and digest original data

Collect and organize relevant parts design, molding process, molding equipment, mechanical processing and special processing materials for use when designing molds.

- Digest the drawings of plastic parts, understand the purpose of the parts, analyze the technical requirements of plastic parts, such as manufacturability and dimensional accuracy. For example, what are the requirements of plastic parts in terms of appearance, color transparency, and performance, whether the geometric structure, slope, and inserts of the plastic parts are reasonable, the allowable degree of welding marks, shrinkage and other molding defects, and whether there is coating or not. Post-processing such as assembly, electroplating, bonding, drilling, etc. Select the size with the highest dimensional accuracy of the plastic part for analysis, and see if the estimated molding tolerance is lower than that of the plastic part, and whether the plastic part that meets the requirements can be molded. In addition, it is necessary to understand the plasticization and molding process parameters of plastics.

- Digest the process data, analyze whether the molding method, equipment model, material specification, mold structure type and other requirements proposed in the process task book are appropriate and whether they can be implemented.

The molding material should meet the strength requirements of plastic parts, and have good fluidity, uniformity, isotropy, and thermal stability. According to the purpose of the plastic part, the molding material should meet the requirements of dyeing, metal plating, decorative properties, necessary elasticity and plasticity, transparency or opposite reflection properties, adhesiveness or weldability. - Determine the molding method

Use direct pressure method, casting pressure method or injection method. - Choose molding equipment

Molds are made according to the type of molding equipment, so you must be familiar with the performance, specifications, and characteristics of various molding equipment. For example, for an injection machine, the following should be understood in terms of specifications: injection capacity, clamping pressure, injection pressure, mold installation size, ejection device and size, nozzle hole diameter and nozzle spherical radius, sprue sleeve positioning ring size, The maximum and minimum mold thickness, template stroke, etc., please refer to relevant parameters for details.

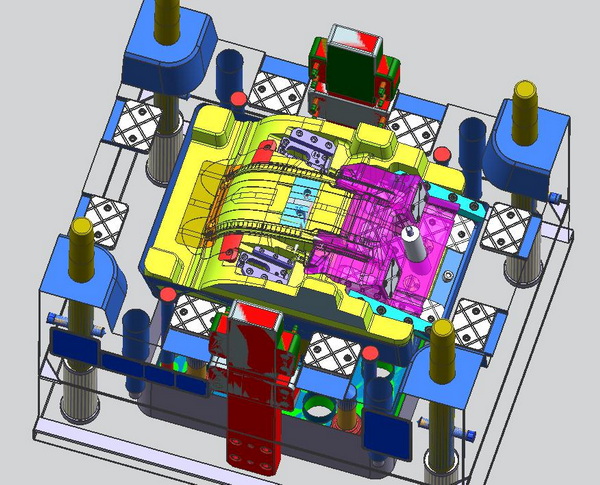

It is necessary to preliminarily estimate the size of the mold and determine whether the mold can be installed and used on the selected injection machine. - Specific structure plan

(1) Determine the mold type

Such as compression molds (open, semi-closed, closed), casting molds, injection molds, etc.

(2) Determine the main structure of the mold type

Choosing the ideal mold structure is to determine the necessary molding equipment and the ideal number of cavities, so that the mold itself can meet the requirements of the process technology and production economy of the plastic part under absolutely reliable conditions. The technological requirements for plastic parts are to ensure the geometric shape, surface finish and dimensional accuracy of the plastic parts. The economic requirements of production are to make the cost of plastic parts low, high production efficiency, continuous working of the mold, long service life, and labor saving.

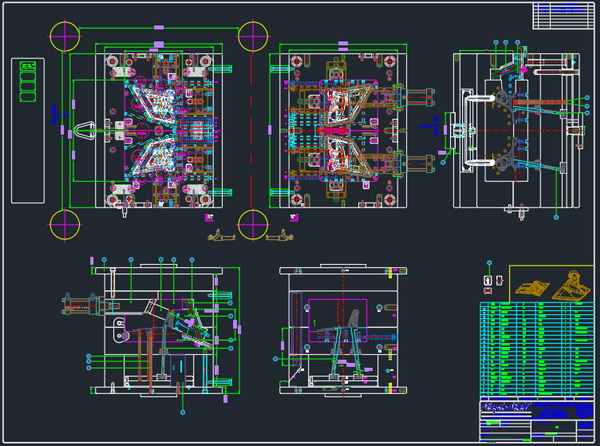

Ⅲ. Drawing mold diagram

It is required to be drawn in accordance with the national drawing standards, but it is also required to combine the factory standards and factory custom drawing methods not specified by the country.

Before drawing the mold assembly drawing, the process drawing should be drawn, and it should meet the requirements of the part drawing and process data. The size guaranteed by the next process should be marked with the words “process size” on the drawing. If there is no other mechanical processing except for repairing the burrs after molding, the process drawing will be exactly the same as the part drawing.

It is best to mark the part number, name, material, material shrinkage rate, drawing ratio, etc. under the process drawing. Usually the process drawing is on the mold assembly drawing.

Ⅳ. Draw all parts diagram

The sequence of disassembling and drawing parts from the mold assembly drawing should be: first inside and then outside, first complicated and then simple, forming parts first, then structural parts.

- Graphic requirements: must be drawn to scale, allowing zoom in or zoom out. The view selection is reasonable, the projection is correct, and the layout is appropriate. In order to make the processing patent number easy to understand and easy to assemble, the graphics should be as consistent as possible with the final assembly drawing, and the graphics should be clear.

- The dimensioning requirements are unified, centralized, orderly and complete. The order of dimensioning is: first mark the main part dimensions and the draft angle, then mark the matching dimensions, and then mark all the dimensions. Mark the mating dimensions first on the non-main parts drawing, and then mark all the dimensions.

- Surface roughness. Mark the most used roughness on the upper right corner of the drawing, such as “Remaining 3.2.” Other roughness symbols are marked on each surface of the part.

- Other content, such as part name, mold drawing number, material designation, heat treatment and hardness requirements, surface treatment, graphic ratio, free size processing accuracy, technical description, etc. must be filled in correctly.

Ⅴ. Proofreading, reviewing, tracing, sending out

A. The content of self proofreading is:

- The relationship between the mold and its parts and the drawing of the plastic part

Whether the material, hardness, dimensional accuracy, structure, etc. of the mold and mold parts meet the requirements of the plastic parts drawings. - Plastic parts

Whether the flow, shrinkage, weld marks, cracks, and demolding angle of the plastic material flow affect the performance, dimensional accuracy, surface quality and other requirements of the plastic parts. Whether the pattern design is insufficient, whether the processing is simple, and whether the shrinkage rate of the molding material is selected correctly. - Forming equipment

Whether the injection volume, injection pressure, and clamping force are sufficient, whether there is any problem with the installation of the mold, the south core of the plastic part, and the demolding, and whether the nozzle of the injection machine and the mouth sleeve are properly contacted. - Mold structure

1). Whether the position of the parting surface and the precision of the finishing process meet the needs, whether there will be overflow, and whether the plastic parts can be guaranteed to stay on the side of the mold with the ejector device after the mold is opened.

2). Whether the demoulding method is correct, whether the size, position and quantity of the promotion rod and push tube are appropriate, whether the push plate will be stuck by the core, and will it cause scratches on the molded parts.

3). Regarding mold temperature adjustment. The power and quantity of the heater; whether the location, size, and quantity of the flow line of the cooling medium are appropriate.

4). The method of processing the undercut of plastic parts and whether the mechanism for removing the undercut is appropriate, such as whether the slider and the push rod in the inclined guide column core pulling mechanism interfere with each other.

5). Whether the position and size of the pouring and exhaust system are appropriate. - Design drawings

1). Whether the placement of the mold parts on the assembly drawing is appropriate, whether it is clearly expressed, and whether there is any omission

2). The part number, name, production quantity, in-house or outsourcing of the part on the part drawing, standard part or non-standard part, matching processing accuracy of the part, correction processing and margin at the high-precision dimension of the molded plastic part , Whether the material, heat treatment, surface treatment, and surface finishing degree of mold parts are marked and clearly described.

3). The working dimensions and matching dimensions of the main parts, forming parts. The size figures should be correct and do not cause the manufacturer to convert.

4). Check the view positions of all parts drawings and assembly drawings, whether the projection is correct, whether the drawing method meets the drawing national standard, and whether there is any missing size. - Check processing performance

(Whether the geometric structure, view drawing method, size mark, etc. of all parts are conducive to processing) - Recalculate the main working size of auxiliary tools

B. Professional proofreading is carried out in principle according to the designer’s self proofreading project; however, it should focus on structural principles, process performance and operational safety.

When drawing a picture, it is necessary to digest the figure first, draw according to the requirements of the national standard, and fill in all the dimensions and technical requirements. Self-study and sign after the scan.

C. Submit the sketched base map to the designer for proofreading and signing. The customary practice is to review by the relevant technical personnel of the tool manufacturer, countersign and check the manufacturing process, and then send it out.

D.. Write manufacturing process card

The technical staff of the tool manufacturing unit compiles the manufacturing process card, and prepares for the processing and manufacturing.

In the manufacturing process of mold parts, inspection should be strengthened, and the focus of inspection should be on dimensional accuracy. After the mold is assembled, the inspector will inspect the mold according to the mold inspection table. The main thing is to check whether the performance of the mold parts is good. Only in this way can the manufacturing quality of the mold be slang.

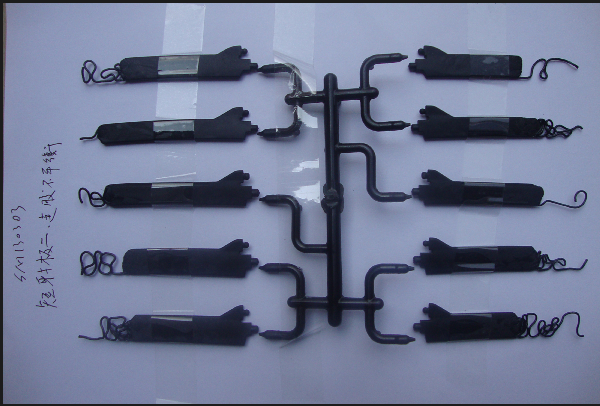

Ⅵ. Trial and repair

Although the mold design is carried out under the expected process conditions when the molding material and molding equipment are selected, people’s understanding is often imperfect. Therefore, after the mold processing is completed, a trial test must be carried out to see the molded part. How is the quality. After discovering that it is always the case, repair the model to eliminate errors.

There are many types of undesirable phenomena in plastic parts, and the reasons are also very complicated. There are reasons for molds and process conditions. The two are often intertwined. Before repairing the mold, according to the actual situation of the undesirable phenomenon of the plastic part, a detailed analysis and research should be carried out, and the remedy method should be proposed after finding the cause of the defect of the plastic part. Because the molding conditions are easy to change, the general approach is to change the molding conditions first, and only consider repairing the mold when the changing molding conditions cannot solve the problem.

You should be more careful when repairing molds, and you should not act rashly if you are not sure. The reason is that once the mold conditions are changed, no major transformation and restoration can be made.

Ⅶ. Organize data and archive

After the mold is tested, if it is not used temporarily, it should completely wipe off the mold release residue, dust, oil, etc., apply butter or other anti-rust oil or anti-rust agent, and keep it in the storage place.

From the beginning of the design of the mold to the completion of the mold processing and inspection, the technical data generated during this period, such as the task book, the part drawing, the technical specification, the mold assembly drawing, the mold part drawing, the base drawing, the mold design manual, and the inspection record Tables, trial and repair records, etc., shall be systematically sorted, bound, numbered and archived in accordance with regulations. This seems very troublesome, but it is very useful for repairing the mold in the future and designing a new mold.

In general, the mold making process is as follows:

Drawing review—material preparation—processing—mold base processing—mold core processing—electrode processing—mold parts processing—inspection—assembly—flying mold—testing—production