Precision manufacturing mainstream processing technology introduction

With the rapid development of science and technology, more and more processing techniques have emerged in the precision manufacturing industry. However, based on meeting the different needs of customers, from the cost of raw materials to the selection of processing techniques and equipment, it can reflect the comprehensive strength of a company and effectively deal with precision. Create this highly competitive market environment. Based on years of working experience, the author briefly summarized the mainstream processing technology, and shared and discussed with everyone.

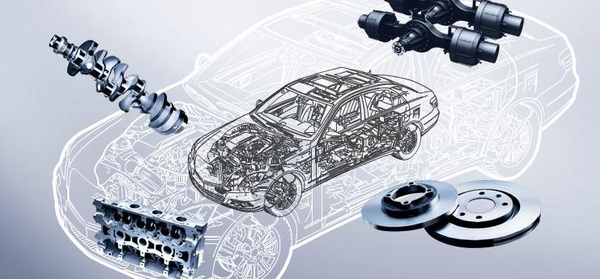

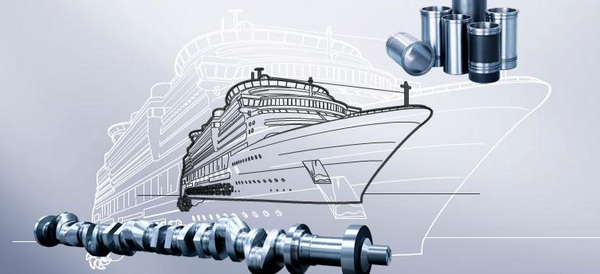

- CNC Machining Center

Machining center, abbreviated as CNC, is a high-efficiency automatic machine tool for processing complex-shaped workpieces composed of mechanical equipment and numerical control system. CNC machining center is an abstract concept, actually called CNC machine tool in general, including computer milling machine (multi-axis) wire cutting machine, spark machine, CNC grinder, etc. The products that can be processed are all-inclusive, so what we can see and touch basically has their labor. It is the core of modern industry and a symbol of the national industrial technology level.

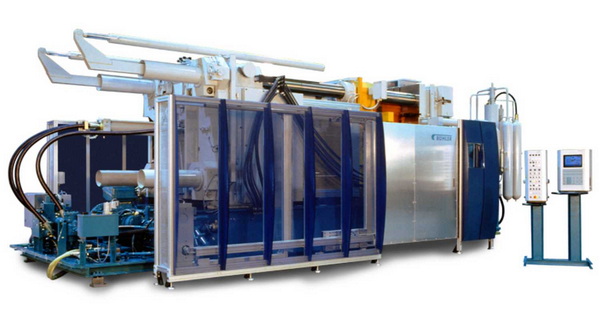

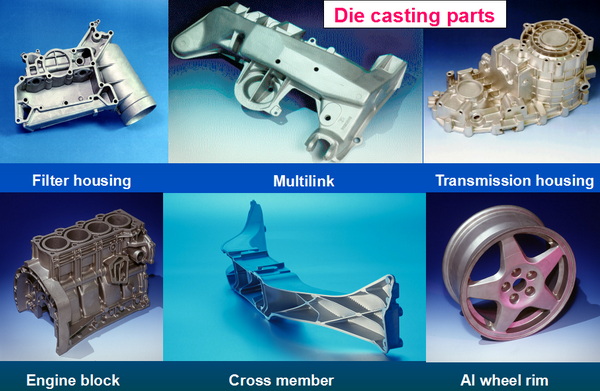

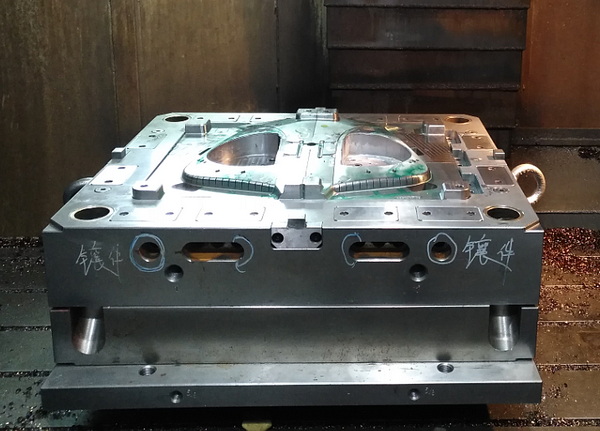

- Die casting process

Die-casting: high-temperature molten metal, filling the cavity quickly under certain conditions under high-speed and high-pressure conditions,And the rapid cooling process under a certain pressure.

- Injection molding process

Plastic mold, short for a combined plastic mold used for compression molding, extrusion molding, injection, blow molding and low foam molding

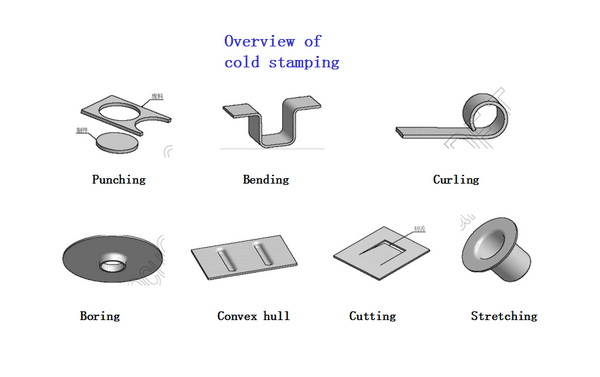

- Stamping process

Stamping: Press and die to apply pressure to materials such as plates, strips, pipes and profiles to separate or plastically deform the materials to obtain the required shape and size of the processing method . Classified by process nature: (1) Blanking dies such as blanking dies, punching Hole die, cutting die, notch die, cutting Trimming tool such as side mold and sectioning mold (2) Bending tool (3) Drawing tool (4) Forming tool

5.Laser processing technology

Laser processing technology collection:

Laser rapid prototyping/laser cutting/laser welding/laser engraving/ laser drilling/laser etching

6.Other processing technology

Water knife cutting processing etc