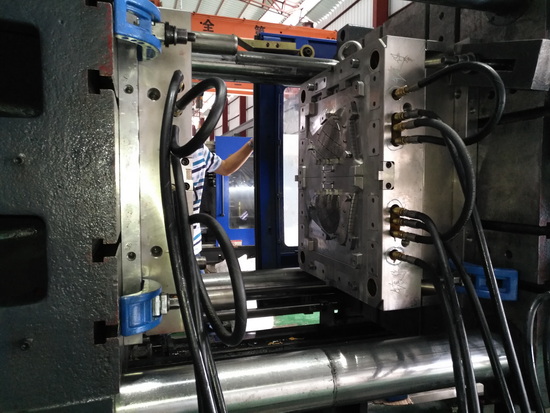

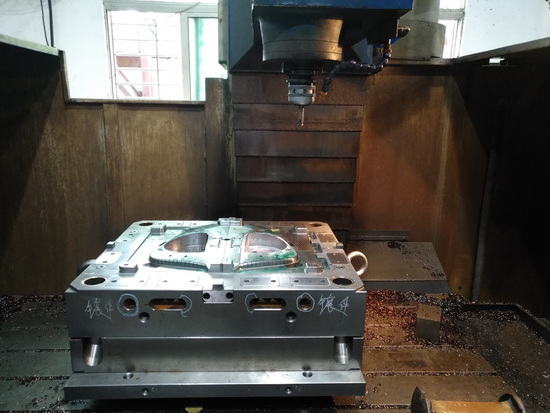

プラスチックモールド粘膜治療計画

There are often some problems when molding injection molds. Such as mold sticking, parting surface burrs, weld lines, warping

Song etc. So how to solve these common problems is worth our study. It can bring convenience for future work.

stick mold

Injection mold sticking is divided into sticking front mold and sticking back mold, depending on the situation, the reasons for sticking mold:

(1) Poor polishing, such as sticking to the front mold, may be because the polishing of the rear mold is better than that of the front mold.

The mold is directly glued to the front mold during the production process.

(2) The design of the drafting slope may be unreasonable. In theory, the drafting slope of the front die is larger than that of the rear die, and the drafting slope is

If the degree is reversed, it may also cause the product to stick to the front mold.

(3) There is a vacuum when the front mold is opened, and the product is directly sucked into the front mold, which cannot be demolded normally.Box products are more common.

(4) The post-die sticking may be due to poor polishing, the demolding slope is too small, and there are upside-down buttons on the die.

(5) The mold temperature is too low at the beginning, and the product’s holding force to the mold is too large.After understanding the reasons why the mold sticks to the mold during trial and production, the defect problem of the plastic mold sticking to the mold is solved.

Solved, the method: the mold polishing front mold is better than the rear mold, and for products with more rear mold ribs, it is necessary to increase Demoulding slope, but it depends on the processing of the product; for shells, boxes and other products, if the front mold exists when the mold is opened

For vacuum, the front mold needs to be exhausted to eliminate the influence of vacuum. Some products also need to be exhausted in the rear mold: if the product structure has requirements for mold temperature, the mold temperature should be increased when the mold is started to reduce the rigidity. The influence of the low mold temperature on the product’s holding force; for the characteristics of the plastic raw materials of the product, set reasonable injection process parameters to reduce the possibility of mold

プラスチックモールド粘膜治療計画