ビンダンダンは2022年の北京冬季オリンピックで最も人気のある贈り物になります

With its cute appearance and the ability of “carrying goods” in the Winter Olympics, the mascot “Bing Dwen Dwen” appeared “hard to find”. At present, Bing Dwen Dwen mascot dolls and other figurines have been sold out, and many netizens have left messages asking the official to replenish the goods as soon as possible. After receiving the replenishment order, the manufacturer also started to work overtime without stopping.

1 Make the “pier” first to make the shell mold

Lin Cunzhen, a senior expert at the Cultural Activities Department of the Beijing Winter Olympics Organizing Committee, said, “A panda is an ordinary panda, and it becomes Bingdundun because of its shell.” And it is this silicone shell that brings Bingdundun to the manufacturer. problem.

How Bing Dwen Dwen was born

As the manufacturer of Bing Dwen Dwen silicone shell, Liu Ming, manager of Dongguan Zhongsheng Silicone Rubber Products Co., Ltd., introduced that in order to achieve large-scale production of Bingdundun silicone shell, an accurate mold must be made first, and the mold must be cleaned and wiped. , and then polished, and then put the silicone on the mold and send it to the machine for shaping. The process of demolding should be very delicate, and there should be no damage. After completion, the Olympic rings and rainbow strips must be integrated into the product.

Five Steps of Bing Dwen Dwen Shell Production

The production process of Bing Dwen Dwen silicone shell belongs to a kind of molding. The main production process of molded silicone rubber products is a silicone processing process in which silicone rubber raw materials are formed into products by heating and pressurizing in a closed mold cavity. Usually, the raw materials are uniformly stirred into a mixed rubber by a mixer, and then the mold is moved into the vulcanization molding machine. Then close the mold and pressurize it to form and solidify or vulcanize it, and then demold it to obtain a silicone product. This process is suitable for the processing of thermosetting materials.

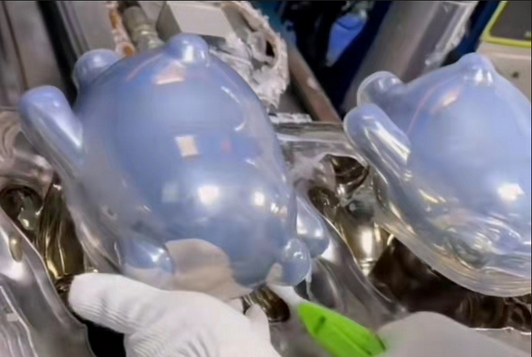

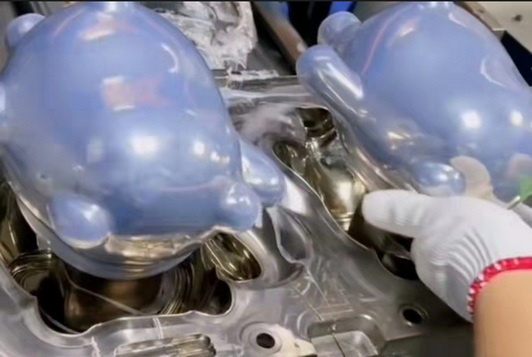

In the workshop of the factory, two sets of Bing dwen dwen pier shell molds weighing several hundred kilograms are “lying” on the machine tool. As long as the raw materials are in place, the silicone shell can be pressed non-stop. However, the size of the Bing Dwen Dwen silicone shell is large, which is different from other small products that can produce dozens of products in one mold. A set of Bingdundun molds can only produce two ice shells at a time. One machine does not stop working, and two sets of molds can be produced in one day. You can only make up to 800 ice crusts.

2 small silicone case to overcome many difficulties

Some people may think that the production process of Bingdundun silicone shell is not too difficult. After the product sample is confirmed, it is like a stepping stone. In order to realize the mass production of icedundun silicone shells, silicone product manufacturers need to overcome the following two difficulties in order to produce shells with ice shell texture.

▶Difficulty 1: Uncooked and uncooked silicone rubber products One of the main reasons for poor products is the generation of air bubbles in silicone rubber products. The reason for the bubbles is that the product is placed in an improper way or the number of exhausts is not enough, which causes the raw materials to be trapped in the cavity, and the air in the cavity is not completely discharged. processing method to solve.

▶Difficulty 2: Silicone rubber products are difficult to demould. The product structure is complex, and the internal air-stick mold is generated during processing; the viscosity of the product raw material is too large, resulting in a low hardness and softness of the product; the surface of the mold is fine and thin, and the surface has small rough serrations.

The above three points will cause the problem of difficult demoulding. Smart manufacturers provide solutions for different reasons: when the mold structure is complex, Teflon can be sprayed on the surface of the product to quickly demold the product; trapped air in the product Multiple sandblasting release agents can be added to the specified core to increase the number of exhausts; when the fluidity of the raw materials is insufficient, the raw materials or vulcanizing agents can be replaced to improve the fluidity of the product; when the hardness is low, the weight of the raw materials needs to be reduced ; When the surface of the mold is rough, you can first sandblast and sand the surface of the mold; if it is not possible, you must prepare a precision milling cutter for fine milling or polishing.

From the video above, it can be seen that the efficiency of workers’ demoulding is relatively high, and the shell is transparent and feels good. The success of Bing Dwen Dwen silicone case is inseparable from the manufacturer’s superb technology and experience, as well as strict control over the production process of silicone products. Don’t worry, the manufacturers are working overtime to produce, I believe that the wish of “one pier per household” will be realized sooner or later.