塑胶模具外观之-省模各种技术方案

Chemical polishing;

Chemical polishing is to dissolve the microscopically protruding part of the material in the chemical medium preferentially over the concave part, so as to obtain a smooth surface. The main advantage of this method is that it does not require complex equipment, can polish workpieces with complex shapes, and can polish many workpieces at the same time, with high efficiency. The core problem of chemical polishing is the preparation of polishing liquid. The surface roughness obtained by chemical polishing is generally several 10 μm.

Electrolytic polishing;

The basic principle of electrolytic polishing is the same as that of chemical polishing, that is, by selectively dissolving the tiny protrusions on the surface of the material to make the surface smooth. Compared with chemical polishing, the influence of cathode reaction can be eliminated, and the effect is better. The electrochemical polishing process is divided into two steps: (1) Macroscopically leveling the dissolved product diffuses into the electrolyte, and the geometric roughness of the material surface decreases, Ra>1μm. (2) Low-light leveling anode polarization, improved surface brightness, Ra<1μm.

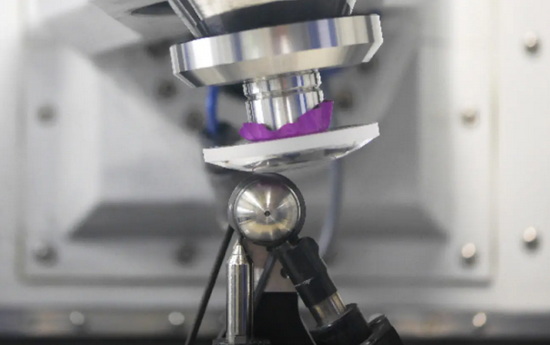

Ultrasonic polishing;

the workpiece is placed in the abrasive suspension and placed in the ultrasonic field together, and the abrasive is ground and polished on the surface of the workpiece by the oscillation of the ultrasonic wave. The macroscopic force of ultrasonic processing is small, and it will not cause deformation of the workpiece, but it is difficult to make and install the tooling. Ultrasonic machining can be combined with chemical or electrochemical methods. On the basis of solution corrosion and electrolysis, ultrasonic vibration is applied to stir the solution, so that the dissolved products on the surface of the workpiece are detached, and the corrosion or electrolyte near the surface is uniform; the cavitation of ultrasonic waves in the liquid can also inhibit the corrosion process, which is conducive to surface brightening.

Fluid polishing:

Fluid polishing relies on high-speed flowing liquid and the abrasive particles carried by it to scour the surface of the workpiece to achieve the purpose of polishing. Commonly used methods are: abrasive jet machining, liquid jet machining, hydrodynamic grinding, etc. Hydrodynamic grinding is driven by hydraulic pressure, so that the liquid medium carrying abrasive particles flows reciprocatingly across the surface of the workpiece at high speed. The medium is mainly made of special compounds (polymer-like substances) with good flowability under lower pressure and mixed with abrasives, and the abrasives can be silicon carbide powder.

Magnetic grinding and polishing;

Magnetic grinding and polishing is the use of magnetic abrasives to form abrasive brushes under the action of a magnetic field to grind workpieces. This method has high processing efficiency, good quality, easy control of processing conditions and good working conditions. With suitable abrasives, the surface roughness can reach Ra0.1μm.